Reverse engineering

Brochure Download

Please click the download button to get the brochure file

Contact Us

If you have any queries about our service please contact us. For international 3D scanning projects, we also collaborate with 3Dgate

- +44 01474 550 934

- 3D Scanning workshop: Hawkspare 2 Green Street Green Rd, Dartford DA2 8DP Kent, United Kingdom

- info@thinkscan.co.uk

Service Details

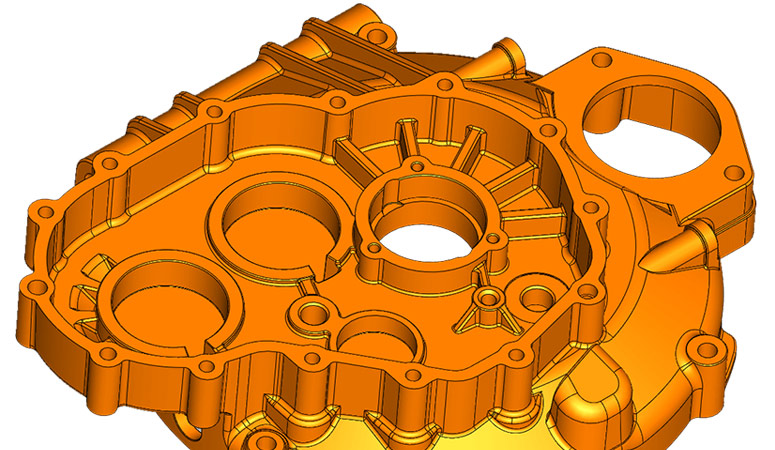

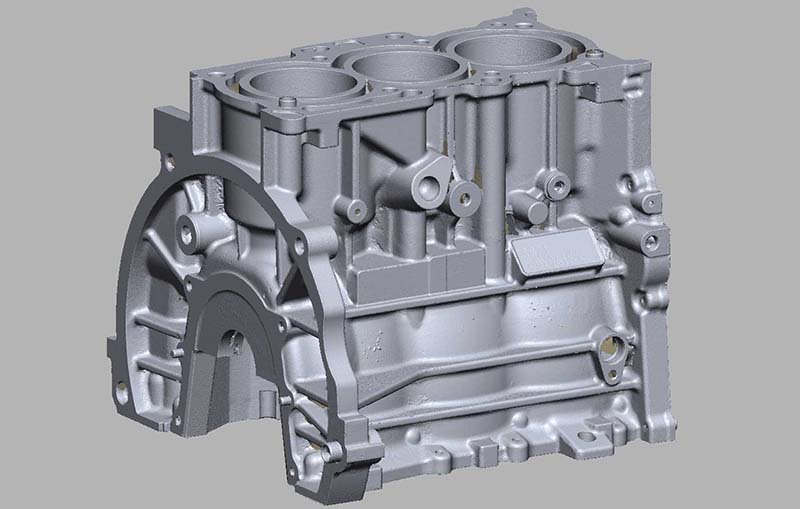

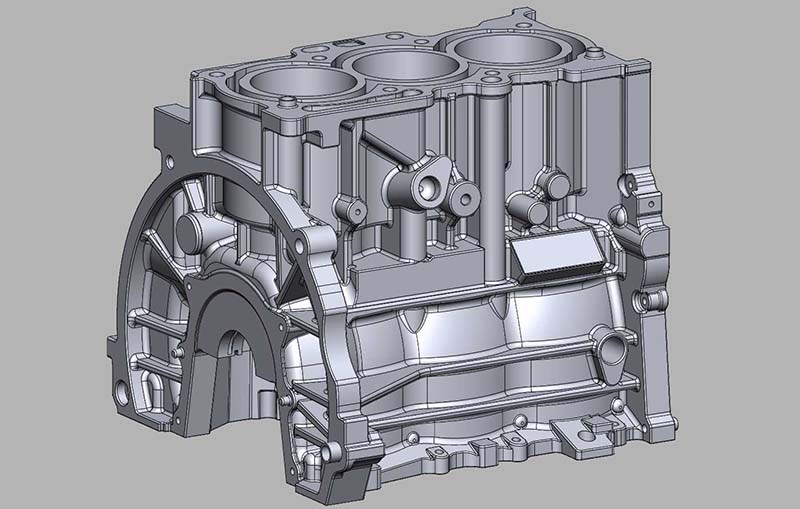

If you need to redesign a part without technical 2D drawing, our CAD Reverse Engineering service can help. For the Reverse Engineering stage we use either Geomagic Design X (parametric CAD redesign) SolidWorks, Geomagic Wrap, Rhinoceros and Autodesk Fusion 360. All CAD files can be exported in several file format such as Iges, Step, Parasolid, Acis and Solidworks (native file).

Open vs Watertight

A 3D scan file can be 'open' or 'watertight'. A watertight 3D file is when the 3D scanner is able to capture 100% of the physical part. Some items can contain hidden areas and/or undercuts. Therefore, it will not always be possible to generate watertight 3D scan data.

For 3D printing or CNC milling, watertight 3D scan data is mandatory and Reverse Engineering is usually required but not always mandatory. In order to make the 3D scan data suitable for 3D printing the easiest option is to CAD redesign the part from 3D scanned data, this is Reverse Engineering ie, 3D scan data is used as 'guide' to recreate the original design intent. Please note: 3D Scanning is a precursor for Reverse Engineering and there is no R.E. without the scan first.

Service Included

- STEP/IGES Conversion from 3D Scan data

- Exporting to Parasolid

- Exporting to CATIA

- Support via email

Frequently Asked Question

Reverse Engineering (R.E.) is the process of measuring a physical part using 3D data acquired by our 3D non-contact 3D scanners. At Thinkscan we are able to CAD redesign a wide range of parts for further engineering. Files converted from scanned data can be exported in several file format such as Iges, Step, Vda, Parasolid, Acis & Solidworks native file with full History Tree. In other words, 3D scanning is the fastest way to collect data from a physical part and create a watertight CAD model which can be transfer to downstream applications, (CAD, CAM, FEA (Finite Element Analysis)

Understanding the Intricacies of Reverse Engineering

Reverse engineering is a crucial process that allows businesses to create digital models of existing physical objects. By understanding the intricacies of reverse engineering, you can harness the full potential of 3D scanning and ensure quality control for your business. At its core, reverse engineering involves capturing the physical measurements and characteristics of an object and using that data to recreate or modify it digitally. This process has numerous applications across industries such as ~Manufacturing, Engineering, and Design. One of the main benefits of reverse engineering is the ability to improve upon existing products or components. By accurately capturing the dimensions and features of an object, engineers and designers can identify areas for enhancement and create improved versions. This can lead to product innovation, increased efficiency, and competitive advantage.

Reverse engineering also plays a critical role in legacy parts replication. When a manufacturer needs to reproduce a discontinued or obsolete component, 3D scanning can capture the necessary data to recreate it accurately. This is especially useful in industries with long lifecycles or those that rely on hard-to-find or custom parts. Additionally, reverse engineering can help businesses in intellectual property protection. By accurately documenting the dimensions and features of their own products, companies can establish evidence of their design and deter counterfeiting or intellectual property infringement.

With our professional 3D scanning service in the UK, you can benefit from our expertise in reverse engineering. Our state-of-the-art equipment and experienced team will ensure that we accurately capture the intricate details and dimensions of your physical objects, allowing for efficient digital recreation and modification.