3D scanning Service for automotive Aftermarket Parts

In the fast-paced world of Automotive Aftermarket and Tuning, staying ahead of the competition is crucial. That's why we're excited to introduce our cutting-edge 3D scanning service, designed specifically for the Automotive Industry. With our advanced technology and expertise, we can help you take your tuning game to the next level. Keep reading to find out more about our innovative 3D scanning service and how it can give you the edge in the fast lane.

Revving Up Your Aftermarket Business with 3D Scanning, CAD Redesihgn (Reverse Engineering) & Rapid Prototyping for small batch Production

When it comes to the fast-paced world of automotive tuning, staying ahead of the competition is crucial. That's where our revolutionary 3D scanning service comes in. With our cutting-edge technology and expertise, we can help rev up your aftermarket business and give you the competitive edge you need to dominate the fast lane. Our Professional 3D scanning service is specifically tailored for the Automotive Industry, providing you with unparalleled precision and dimensional accuracy. By 3D scanning your automotive parts we can create highly detailed digital models that can be used for a variety of purposes. Whether you're looking to create custom car parts, improve performance, or streamline your manufacturing processes, our 3D scanning service is the key to unlocking your automotive tuning potential.

By utilising our 3D scanning service, you'll benefit from faster turnaround times and reduced costs. Traditional methods of creating custom car parts can be time-consuming and expensive. However, with 3D scanning, we can quickly capture the geometry of your existing (or no longer available) automotive parts and generate digital models that can be easily modified and reproduced. This not only saves you time but also allows for greater design flexibility and cost efficiency. Additionally, our 3D scanning service supports Reverse Engineering, which is crucial for automotive tuning. By scanning an existing part, we can recreate it digitally, allowing for modifications and improvements to be made. This process is essential for developing aftermarket parts that are compatible with existing vehicles, giving you the freedom to customise and enhance performance without limitations.

Looking towards the future, 3D scanning is set to revolutionise the automotive tuning industry. As the technology continues to evolve, we can expect even greater advancements in precision, speed, and affordability. Whether it's 3D printing, rapid prototyping, or advanced simulations, 3D scanning will play a pivotal role in shaping the future of automotive tuning.

For more information:

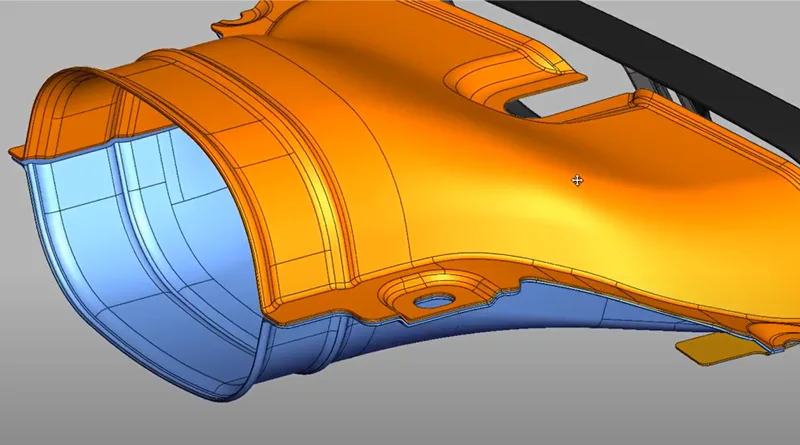

Mercedes AMG Exhaust tip + body. 3D scan + Reverse Engineering

Leveraging 3D Scanning for Reverse Engineering

The process of Reverse Engineering with 3D scanning offers unparalleled design flexibility. We can experiment with different configurations a sizes us to explore innovative design possibilities that were previously unimaginable. By accurately capturing every detail of the original part, we can ensure that the customised version not only looks great but also performs at its best.

Not only does 3D scanning for automotive enable us to create highly detailed digital models, but it also streamlines the manufacturing process. Traditional methods of creating custom car parts can be time-consuming and expensive, requiring manual measurements and prototypes. With 3D scanning, we can skip these steps and go straight to production, reducing turnaround times and costs significantly. This means that you can bring your custom car parts to market quicker, staying ahead of the competition in the fast-paced automotive aftermarket industry.