3D Services for Automotive Industry

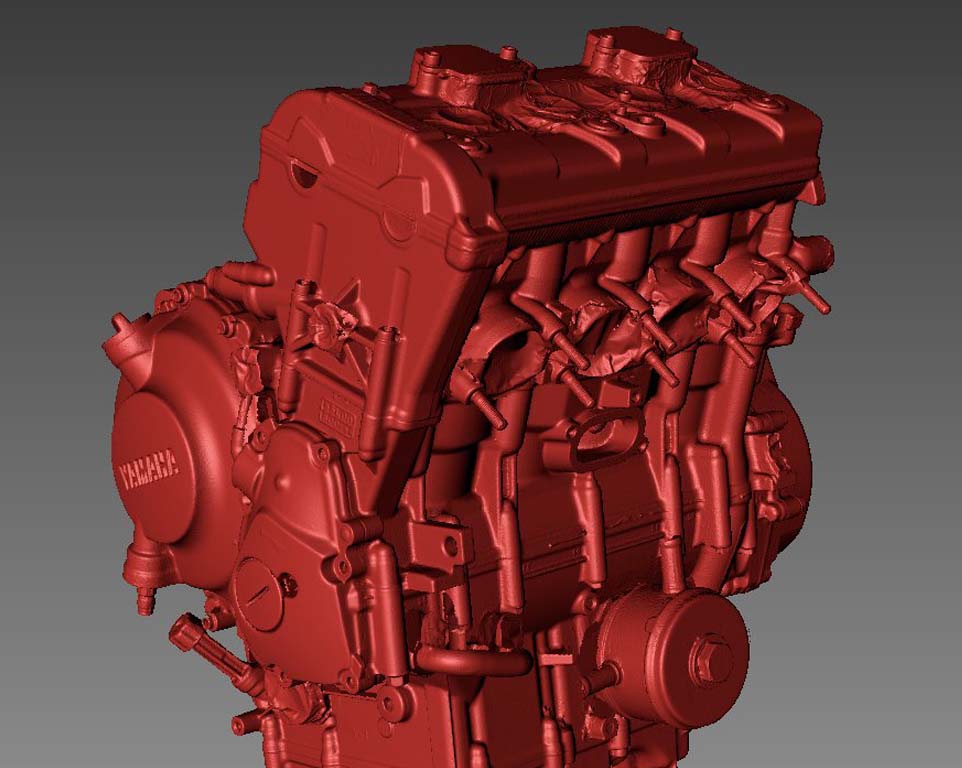

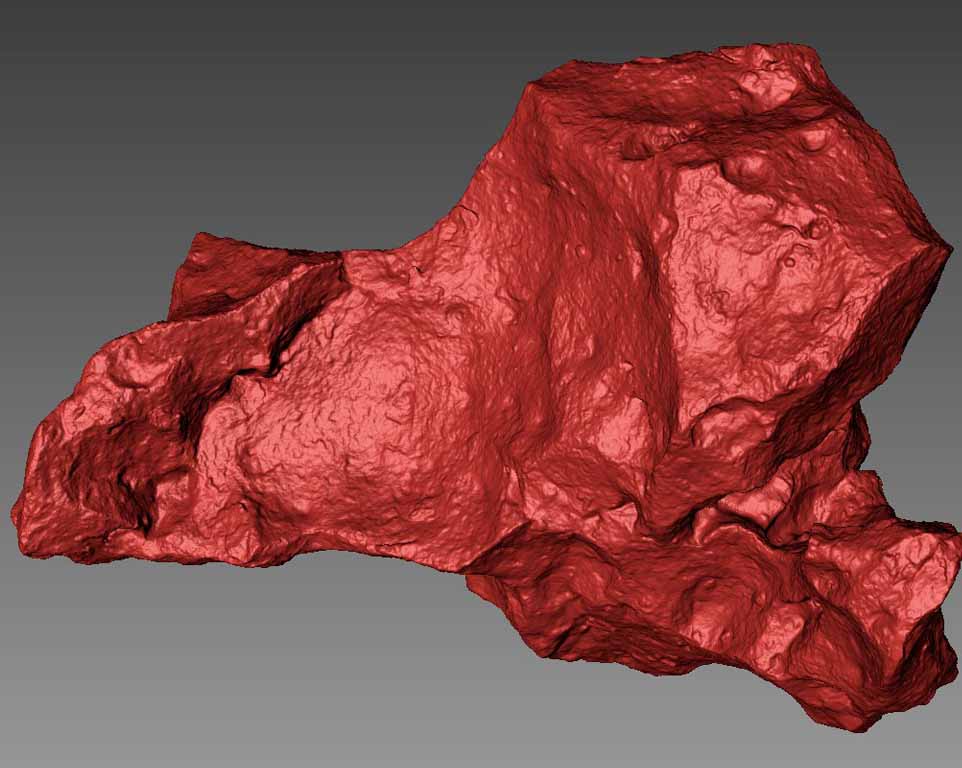

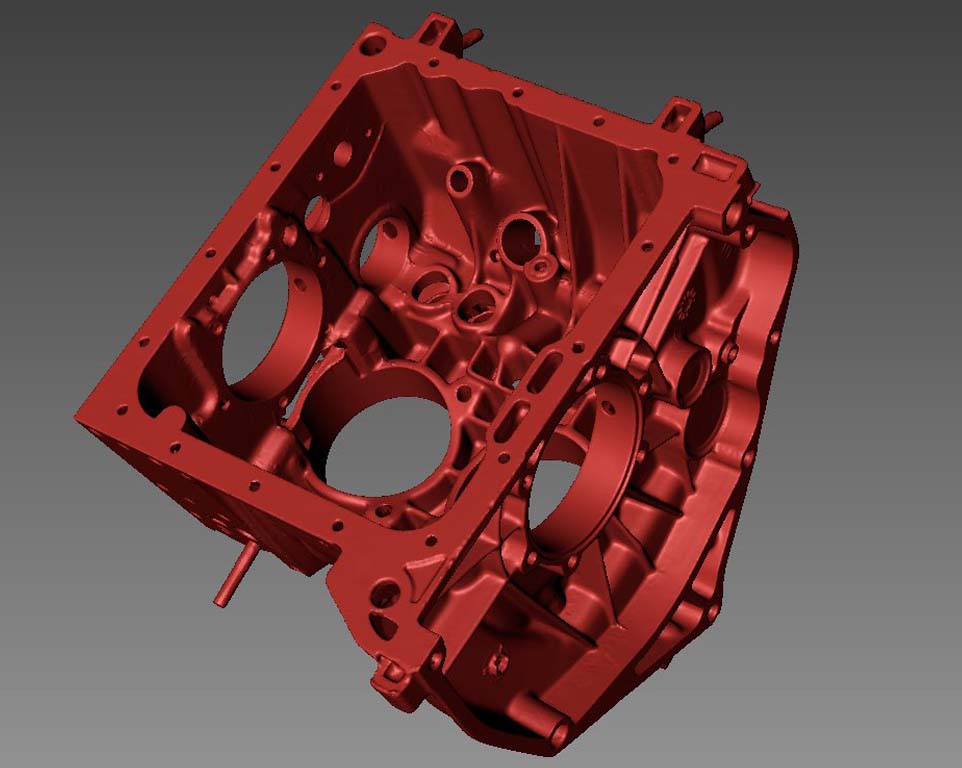

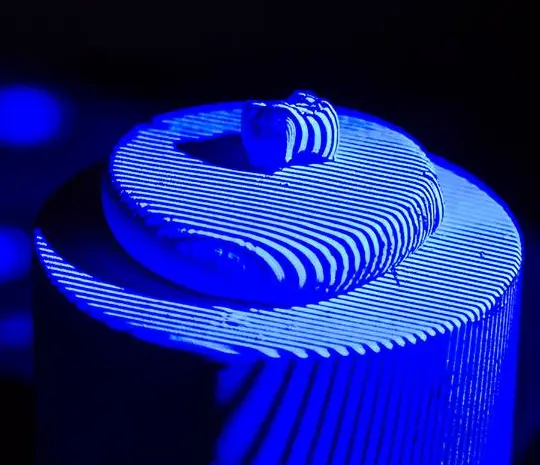

Aurora 3D is an advanced Structure Light 3D Scanner which adopts the raster scanning and auto-registration technology carries out the scanning in a Non-Contact way. It offers efficiency, High Dimensional Accuracy and Resolution. Aurora 3D is ideal for the scanning and measuring of complex free-form surfaces, soft objects, easily wore moulds, and small artifacts. It is mainly applied in product R&D (for example, 3D measuring, 3D digitizing mould file, CAD design, CNC machining, rapid prototyping), Reverse Engineering and 3D inspection (CAV, CAE analysis, etc.).

Non-Contact 3D Measuring

The Aurora 3D is a unique and full customizable optical 3D scanner; while other 3D scanners can be restrictive in their ability to only scan similar sized parts, our solution is different. It offers the capability to scan components of different shapes and sizes simply by changing its field of view. The Aurora 3D is a great solution to 3d scan a variety of object such as:

- Car bodyworks

- Engine Block

- Injection molding Parts

- Shoes & Heel, Lasts etc.

- Small Mechanical Components

- Threads, Gears & sprockets

- Front Bumper, Bonnets etc.

- Motorcycles Parts

From 5 up to 8 Megapixels

Aurora 3D 3.0 Megapixel is able to 3D capture surfaces in exceptional detail with photo texture support. White light technology can scan objects from 10mm up to meters.

Highly-dense point cloud is captured fast during scanning; the 3D data of delicate parts can be obtained quickly. Aurora 3D 5.0 Megapixels is the best option if you want to achieve a very high-dense 3D scan

High-Grade aluminium body construction with anodized black textured coating for high durability and years of use.

Non-contact measuring

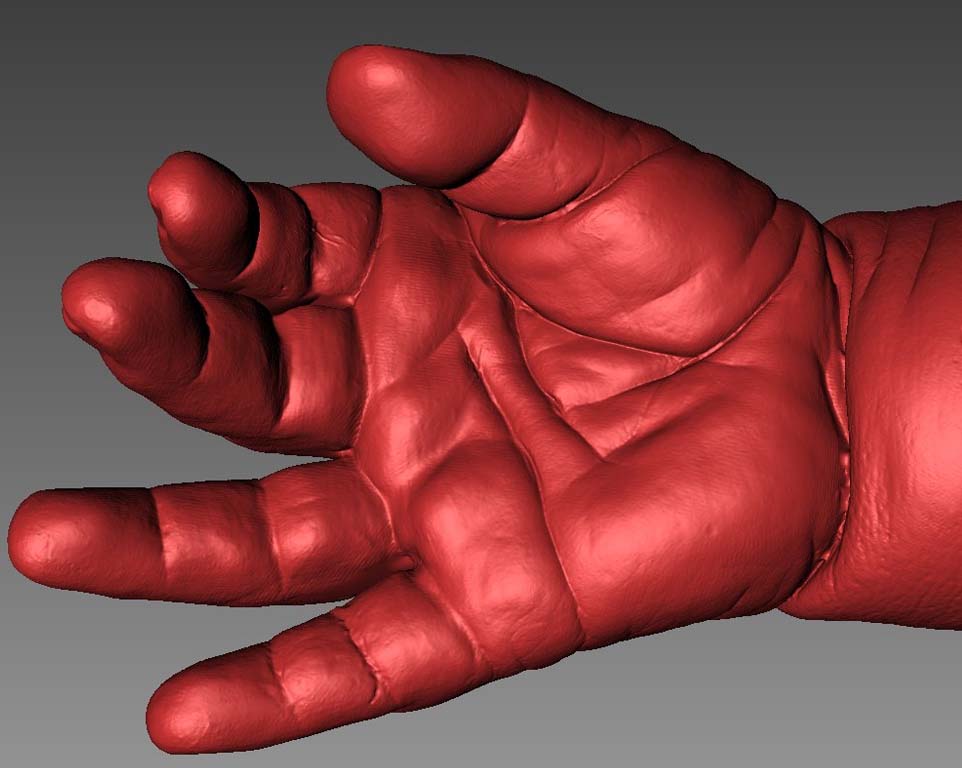

Performing the scanning in a non-contact optical way, high stability, wide application, ideal for the scanning and measuring of complex free form surfaces, soft objects, easily worn moulds, samples.

High Efficiency

Single scanning speed can be less than 3 seconds; the 3D data of an object can be obtained quickly

High Dimensional Accuracy

Measuring precision is tested according to European optical scanners testing standard: VDI/VDE 2634 and single scanning accuracy can reach as high as 0.02mm

High Resolution

Highly dense point cloud is captured fast during scanning; the 3D data of delicate parts can be obtained quickly

Automatic Registration

The scanned objects can be turned and moved during the scanning process, the smart software can perform auto-registration to get a 360 3D data, short alignment time, high precision

Portable 3D Scanner

Small size, portable, especially suitable for scanning huge or heavy objects

User Friendly 3D Scanning

Easy to understand, convenient to operate

High compatibility

The data can be exported as ASC, STL, FBX, OBJ etc, compatible with other software such as SolidWorks, Rhinoceros, Geomagic Design X, PTC Creo, Catia, Siemens NX, Rhinoceros etc.

Easy To Use & Learn

The 3D Scanning software included with the 3D Scanner just takes a few hours to Learnt

High Resolution and Accurate 3D Scans

The Aurora 3D Scanner is a flexible system that is capable of scanning objects of different shapes and sizes by changing its field of view. The scanner cameras can be placed in different preset slots to adjust the field of view. Aurora 3D uses a pair of High-quality stereo Cameras for capturing high-Resolution and accurate 3D scans. The Aurora 3D scanner captures a single scan up to 20µm dimensional accuracy and generates up to ~5 million points per single 3D scan.

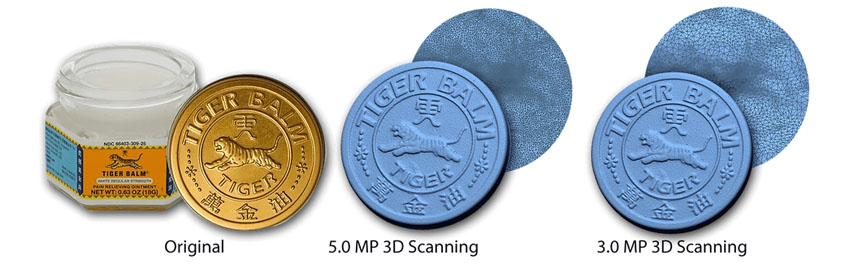

Comparison: Aurora 5.0 MP Vs. 3.0 MP

If your goal is to 3D digitize objects from 100mm up to ~ 2 meters a pair of 3.0 megapixel cameras are a very good choice to achieve High-Quality scans with crisp edges. 5.0 megapixel resolution camera is useful especially if you intend capturing small items such as coins, mechanical thread, dental abutments etc.